Developing Films Using a Dental Film Processor

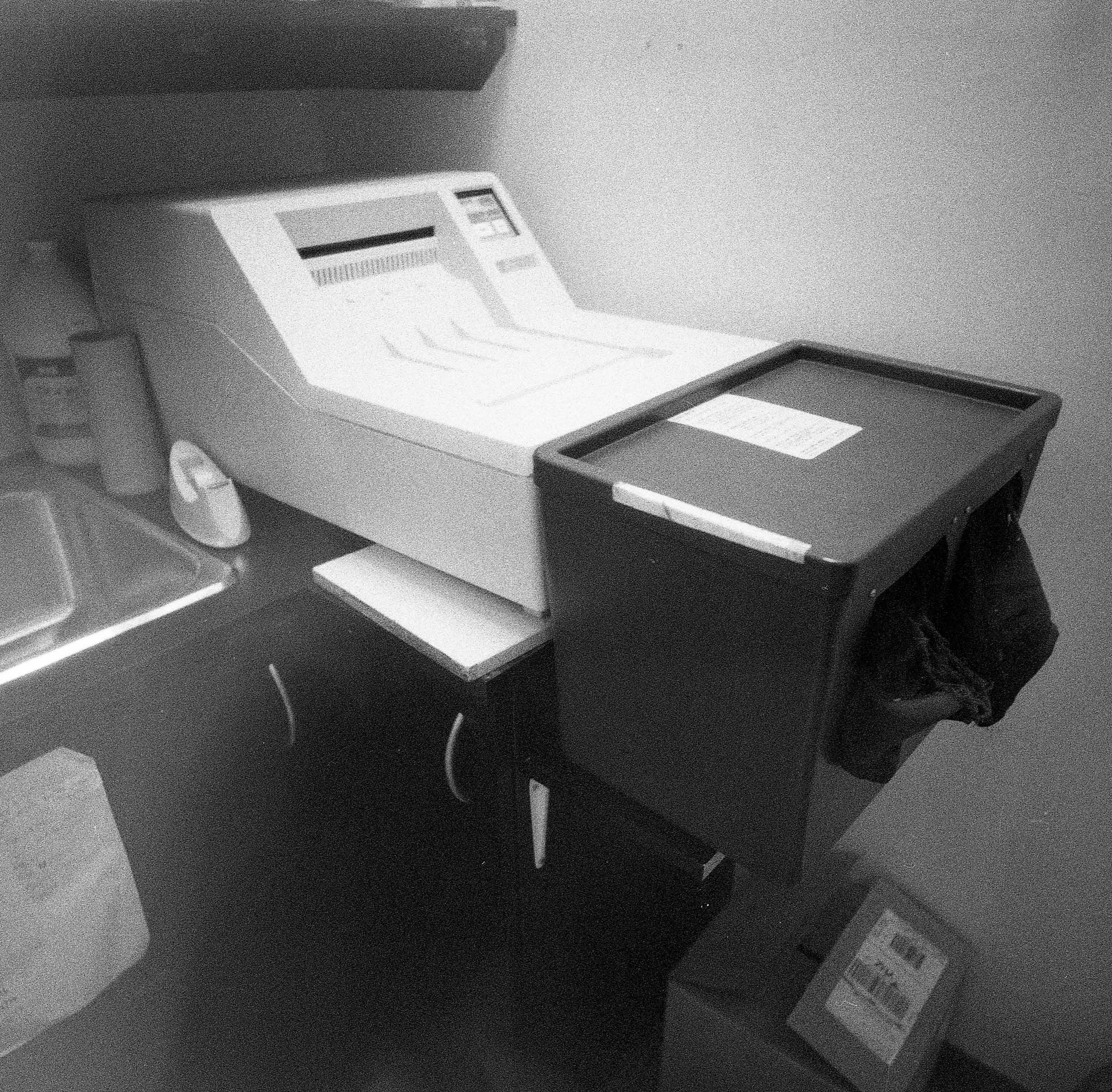

6 19 Share TweetFilm based photography hasn’t been the only casualty of our new digital world. Dental offices around the world have been switching their X-ray systems over from film to digital sensors. As a result there’s been a recent surge in automatic X-ray processors or developers showing up on used goods websites to be purchased secondhand. Many of them have been used hard but they were built exactly for that and should still provide years of dependable service. Parts are also still being made for these units as well and there are still technicians around that know how to repair them.

Why would this be of any interest to a film photographer though?

These X-ray developers have two reservoir tanks. One for developer and another for fixer. They also have a water bath (requires a connection to household water) and more importantly, a dryer. Sound like a certain black and white process that you’re already familiar with? If you were to put your own developer and fixer into these processors the film would come out developed, DRY and spot free in only 4.5 minutes! The obvious benefit of this is your film isn’t hanging around, building a static charge, and drawing in dust onto the emulsion to ruin your photos. These machines hold quite a volume of solution though and require that amount for the photo to develop. Plan your developing wisely as you wouldn’t mix up this amount of chemistry to develop only a single roll of black and white film. This would be an ideal setup for a community darkroom. If you placed a silver recovery unit (essentially a bucket that allows the chemicals to flow out from the top but lets the silver settle in the bottom) then you could conceivably even sell the silver back to a recycler and recoup some of your investment after some time. You would also be practicing more environment-friendly film photography.

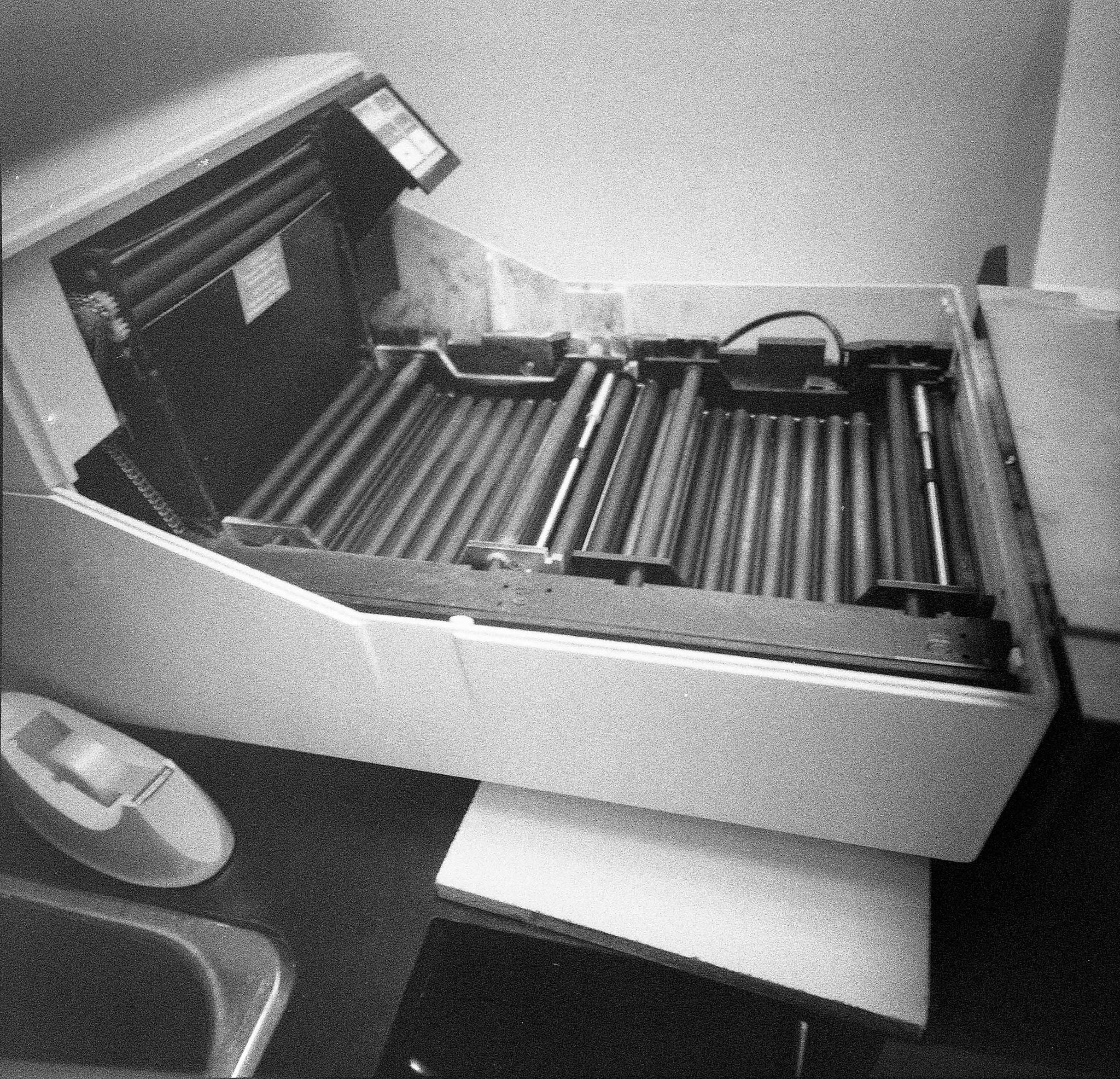

There are a few challenges to work out though. The first is film curl. Because these processors automatically feed your film through the system using a series of rollers any curl in the film can cause the film to wind around one of the rollers rather than transporting the film through. The workaround for this is to securely staple a small 2" piece of stiffer yet still slightly flexible plastic onto the front of your film. This will make your curly film and those rollers play well together. Alternatively, you could ask your local film lab very nicely for some of their tape. They use a special adhesive tape that will stick your film to a plastic leader and it won’t come undone in the solution. They may even let you purchase a roll of it.

The second issue is lateral migration of your film as it feeds in. If you feed your film in on some kind of angle the film will continue along that angle. Eventually the edge of your film will strike the end of the film loading slot and this will result in the folding and creasing of your film. Again, this can be easily avoided by placing your film in the dead center of the loading slot and ensuring it’s feeding in relatively straight.

The last challenge I can foresee is the fact that these processors heat the solutions to 28 degrees Celsius. This will result in an image with considerable contrast. Workarounds could be removing the heater, re-calibrating it (for those of you handy with electronics), or simply switching it on at the very last minute before you start feeding it film. That way the heater hasn’t had time to warm the solutions.

All the photos here are examples of film that were processed with an x-ray developer. Here are some more examples of various film formats developed with an X-ray developer:

110 film

35mm film

120 film

Good luck!

escrito por ces1um el 2017-07-29 #tutoriales #diy-developing #black-and-white-photography #dental-film-processor

6 Comentarios